Log in

Search

Latest topics

» Jim Walkers FireBee - This is going to be funby rdw777 Today at 10:24 am

» **VOTE-ON-THE-NEXT-COX-ENGINE-OF-THE-MONTH** (May 2024)

by GallopingGhostler Today at 7:20 am

» Here we go again... another Lawn-Boy

by rsv1cox Today at 6:50 am

» Norvel Needle Needed

by Greenman38633 Today at 4:02 am

» A prototype Cox Reed-valve marine engine

by roddie Yesterday at 11:51 pm

» My Cox .049 Marine inboard engine

by 1/2A Nut Yesterday at 11:41 pm

» Jim Walker Firebaby

by rsv1cox Yesterday at 7:26 pm

» Roddie-Rigger.. a 2005 original design

by roddie Yesterday at 7:04 pm

» music vids.. some of your favorites

by HalfaDave Yesterday at 6:55 pm

» World's largest weathervane

by Cox International Yesterday at 3:38 pm

» Help Pee Wee tank cap .020

by rdw777 Yesterday at 1:30 pm

» Revivng Some Childhood Classics

by getback Yesterday at 8:21 am

Cox Engine of The Month

Blue printing an Enya engine (this happens to be an .049-II Series #4)

Page 1 of 1

Blue printing an Enya engine (this happens to be an .049-II Series #4)

Blue printing an Enya engine (this happens to be an .049-II Series #4)

Here are two identical "New in the Box" Enya .049-II series #4.

The engine on the left is an older (earlier) version and the one on the right is a newer (later) version.

The earlier version has the "black" coating on it where the newer one doesn't. (cost savings).

The boxes are also a giveaway as the one on the left has the older yellow/red box

whereas the newer one has the black/red box.

One other difference -----the price ---- I wished I paid ¥5500 for these engines! Not the case, more like ¥18,000(each)

Included in the box is the Enya engine instructions which are identical.

Now, to part of the explanation of the title.

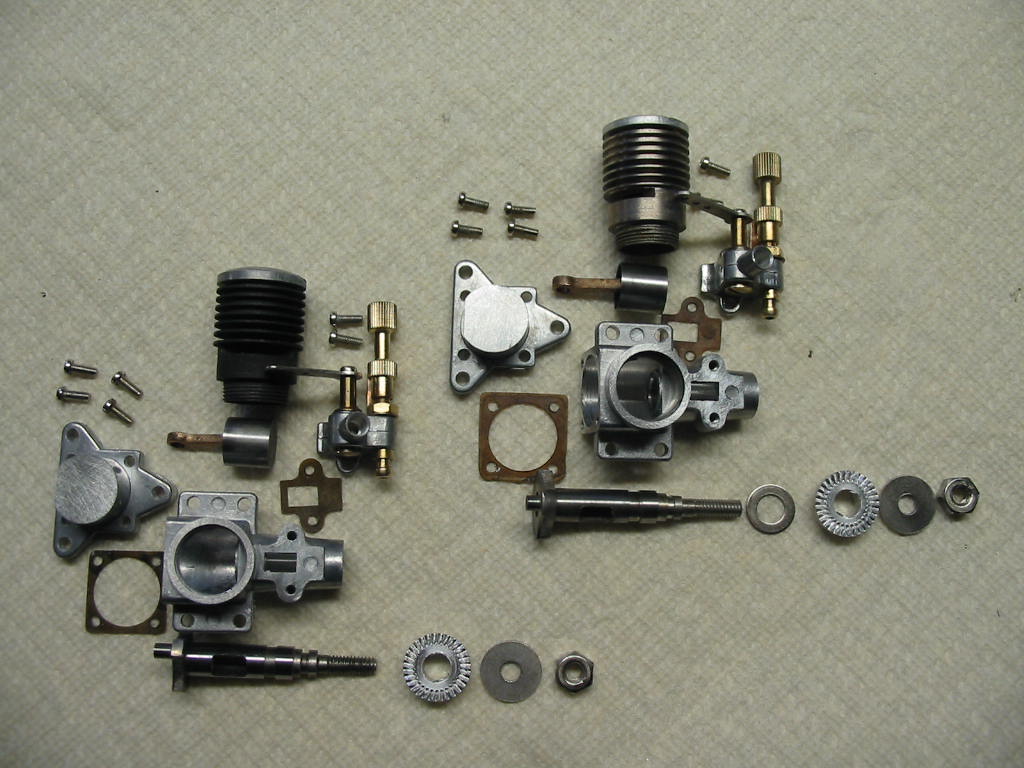

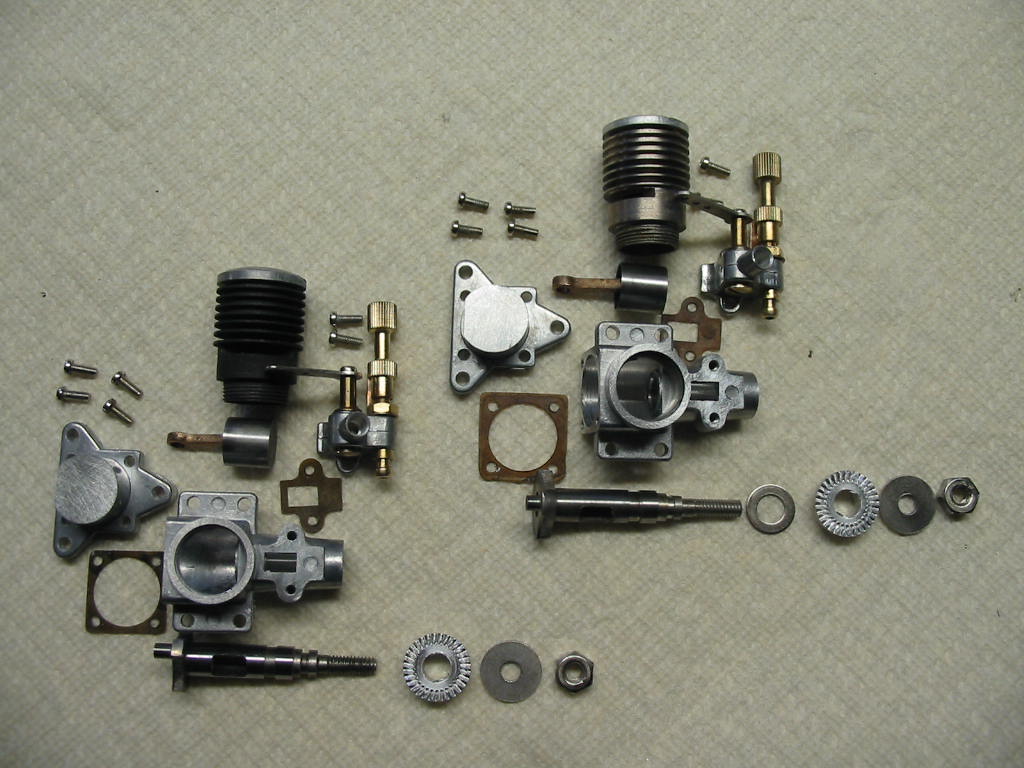

Below are the two engines disassembled (both were stuck -- crank didn't move)

Take a good look in the photo and see what is missing from one engine over the other?

I lined up the parts so that each engine parts are in the same place as the other engine.

Have you found the one missing part on the one engine?

Hint: On the darker cylinder engine.

I have noticed these missing parts on many of the small Enya engines (the 049/06/08 and 10)

It doesn't matter if it is the "older" or "newer" engines.

I think it was a quality control problem missing this small part?

I've been fortunate enough to be able to make the missing part, as Ken Enya doesn't have any "stock" for that part.

And I got some advice from a model engine rebuilder that the part could be made from copper as it would work out well for the application.

Have you the answer?

What is missing is the "Thrust Washer"

I made the missing part (thrust washer) and from there I did some finishing work on the two engines. (detail posting later)

The short of it is:

Surface lapping on mating parts. The shaft to backplate clearance so that the crankshaft pin doesn't gouge into the back plate. Clean-up on the 5-piece piston assembly. I took what I found out in the Mokoken engines and am doing the same on the Enya engines.

After the modifications, the engines were sonic cleaned and reassembled with some Turbine Oil.

The engine on the left is an older (earlier) version and the one on the right is a newer (later) version.

The earlier version has the "black" coating on it where the newer one doesn't. (cost savings).

The boxes are also a giveaway as the one on the left has the older yellow/red box

whereas the newer one has the black/red box.

One other difference -----the price ---- I wished I paid ¥5500 for these engines! Not the case, more like ¥18,000(each)

Included in the box is the Enya engine instructions which are identical.

Now, to part of the explanation of the title.

Below are the two engines disassembled (both were stuck -- crank didn't move)

Take a good look in the photo and see what is missing from one engine over the other?

I lined up the parts so that each engine parts are in the same place as the other engine.

Have you found the one missing part on the one engine?

Hint: On the darker cylinder engine.

I have noticed these missing parts on many of the small Enya engines (the 049/06/08 and 10)

It doesn't matter if it is the "older" or "newer" engines.

I think it was a quality control problem missing this small part?

I've been fortunate enough to be able to make the missing part, as Ken Enya doesn't have any "stock" for that part.

And I got some advice from a model engine rebuilder that the part could be made from copper as it would work out well for the application.

Have you the answer?

What is missing is the "Thrust Washer"

I made the missing part (thrust washer) and from there I did some finishing work on the two engines. (detail posting later)

The short of it is:

Surface lapping on mating parts. The shaft to backplate clearance so that the crankshaft pin doesn't gouge into the back plate. Clean-up on the 5-piece piston assembly. I took what I found out in the Mokoken engines and am doing the same on the Enya engines.

After the modifications, the engines were sonic cleaned and reassembled with some Turbine Oil.

sosam117- Diamond Member

- Posts : 1292

Join date : 2016-03-23

Location : Suburb of Chicago, Illinois

Re: Blue printing an Enya engine (this happens to be an .049-II Series #4)

Re: Blue printing an Enya engine (this happens to be an .049-II Series #4)

It shouldn't be such a big surprise on a plain bearing engine, I think. Thrust washers aren't needed on CL engine (assuming hand starts only), it is only on RC engines and at reduced throttle settings that the crank can tend to move back and forth, creating a bit of rattling noise.

It is quite common to have to "tune" the crank to crankcase play (forward/aft) by adding washers/metal shims or even by modding the thrust plate itself. On PAW engines this is even covered in the manual that comes with the engines.

You do not want to remove the play completely though, some play is needed in order to ensure proper lubrication at the front end of the crank. So error on the large side, in terms of play.

It is quite common to have to "tune" the crank to crankcase play (forward/aft) by adding washers/metal shims or even by modding the thrust plate itself. On PAW engines this is even covered in the manual that comes with the engines.

You do not want to remove the play completely though, some play is needed in order to ensure proper lubrication at the front end of the crank. So error on the large side, in terms of play.

Surfer_kris- Diamond Member

- Posts : 1906

Join date : 2010-11-20

Location : Sweden

Re: Blue printing an Enya engine (this happens to be an .049-II Series #4)

Re: Blue printing an Enya engine (this happens to be an .049-II Series #4)

My 1965 OS Max .10R/C I acquired in 1974 from now long gone Hobby Shack has a stainless steel thrust washer. Mr. Ogawa recognized a need for it, and so spared no expenses in providing it. Those OS's are jewels of an engine. With only a ganged rotating exhaust baffle plate to the carb link, at 3.1 oz. weight, they make a nice upgrade to half-A's with considerably more power swinging a 7x4 prop than a .049 reedie. Noise wise, at full throttle same noise volume as a reedie; at half throttle like muffled; at idle, ultra quiet. (This is why I have 3.)

Out of curiosity, I did a look-see on Brinell Hardness for various metals, https://drill-hq.com/2011/11/hardness-scale-for-various-materials/ . Pure copper is softer than aluminum, K&S sheet is 110 Copper also used in electrical service.

Regardless, Cox used Phenolic washers on their Tee Dee engines which is softer, so probably a non-issue.

Advantages of "rolling your own" as @sosam117 did, is you can have on hand extra replacements. Since most needed in idle if a tractor engine, then it is there only to prevent crankshaft slap. Time would tell but like in all things, the ease in punching them out makes for a useful "gap filler".

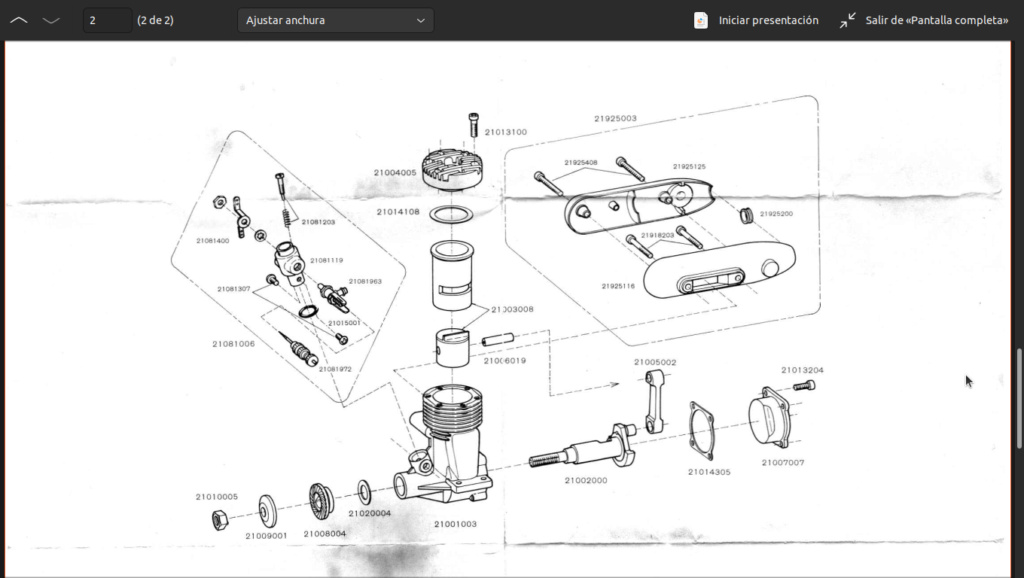

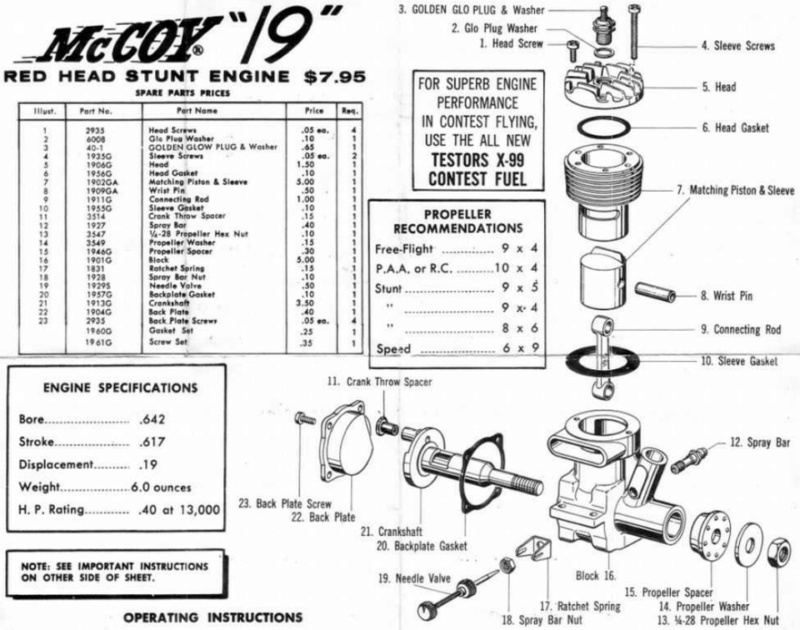

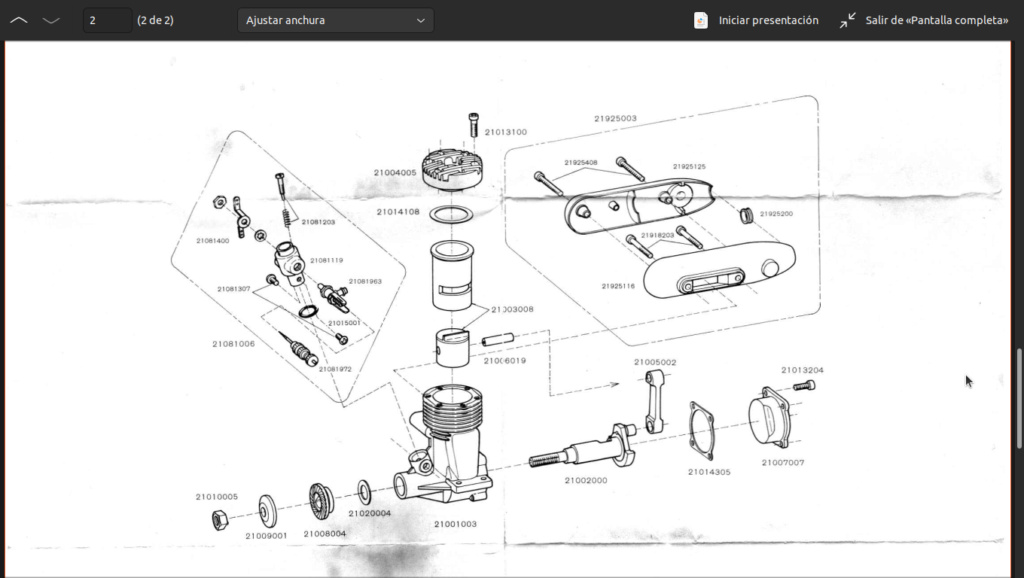

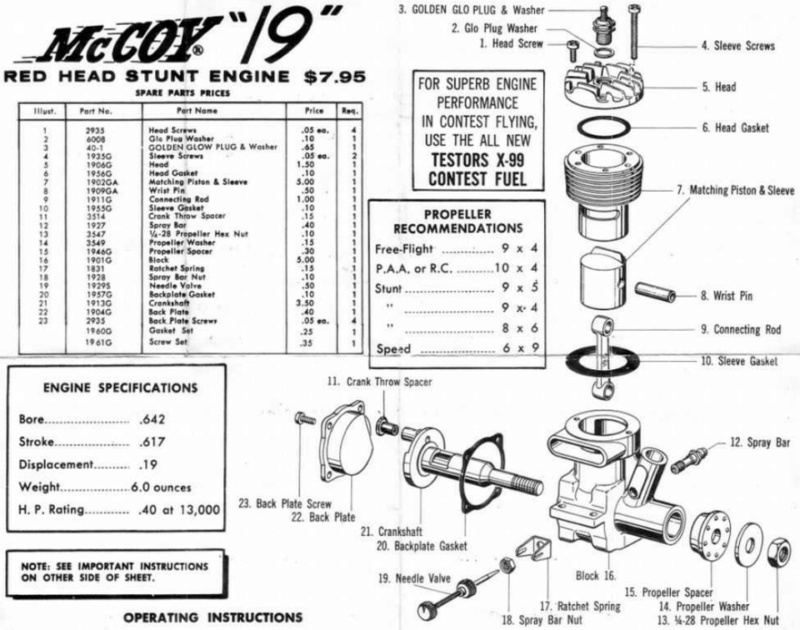

It may also be useful on the legacy cross scavenge engines such as the Testor McCoy's and K&B Torpedoes and Stallions. They usually have a liberal amount of play.

Both use a nylon Crank Throw Spacer to prevent the hollow crankshaft connecting rod pin and connecting rod end from contacting the backplate. I do hand flipping chicken stick style versus any form of electric start, because it is easy to damage the nylon Spacer.

With a lack of this special nylon Spacer, I have found that an aluminum 1/8th inch dia. pop rivet fits perfectly without the shank. However, it being a tougher aluminum could possibly cause galling to the backplate especially if an electric starter is used, but I hand start.

Otherwise, during run, it floats, so I dressed the domed rivet head with a file to remove burrs then polished it. Long term, I don't think it will be a problem. But, I only do this because they are my engines and I am free to do with them as I like.

Out of curiosity, I did a look-see on Brinell Hardness for various metals, https://drill-hq.com/2011/11/hardness-scale-for-various-materials/ . Pure copper is softer than aluminum, K&S sheet is 110 Copper also used in electrical service.

Regardless, Cox used Phenolic washers on their Tee Dee engines which is softer, so probably a non-issue.

Advantages of "rolling your own" as @sosam117 did, is you can have on hand extra replacements. Since most needed in idle if a tractor engine, then it is there only to prevent crankshaft slap. Time would tell but like in all things, the ease in punching them out makes for a useful "gap filler".

It may also be useful on the legacy cross scavenge engines such as the Testor McCoy's and K&B Torpedoes and Stallions. They usually have a liberal amount of play.

Both use a nylon Crank Throw Spacer to prevent the hollow crankshaft connecting rod pin and connecting rod end from contacting the backplate. I do hand flipping chicken stick style versus any form of electric start, because it is easy to damage the nylon Spacer.

With a lack of this special nylon Spacer, I have found that an aluminum 1/8th inch dia. pop rivet fits perfectly without the shank. However, it being a tougher aluminum could possibly cause galling to the backplate especially if an electric starter is used, but I hand start.

Otherwise, during run, it floats, so I dressed the domed rivet head with a file to remove burrs then polished it. Long term, I don't think it will be a problem. But, I only do this because they are my engines and I am free to do with them as I like.

GallopingGhostler- Top Poster

Posts : 5330

Join date : 2013-07-13

Age : 70

Location : Clovis NM or NFL KC Chiefs

Re: Blue printing an Enya engine (this happens to be an .049-II Series #4)

Re: Blue printing an Enya engine (this happens to be an .049-II Series #4)

Surfer_kris wrote:It shouldn't be such a big surprise on a plain bearing engine, I think. Thrust washers aren't needed on CL engine (assuming hand starts only), it is only on RC engines and at reduced throttle settings that the crank can tend to move back and forth, creating a bit of rattling noise.

It is quite common to have to "tune" the crank to crankcase play (forward/aft) by adding washers/metal shims or even by modding the thrust plate itself. On PAW engines this is even covered in the manual that comes with the engines.

You do not want to remove the play completely though, some play is needed in order to ensure proper lubrication at the front end of the crank. So error on the large side, in terms of play.

Ken has given me information on the min/max end play on the crankshaft.

Ken gave me the reason as to why there is a certain amount of play as the aluminum crankcase will expand more than the steel crankshaft. Expansion rates of aluminum and steel are not the same.

Min. on the 049/06/08 and 10 is .500mm (.020") / Max. 1.00mm (.040")

The copper washer I make stops on the crankshaft to where it is not really a shim but a stop between the crankcase and the prop driver washer.

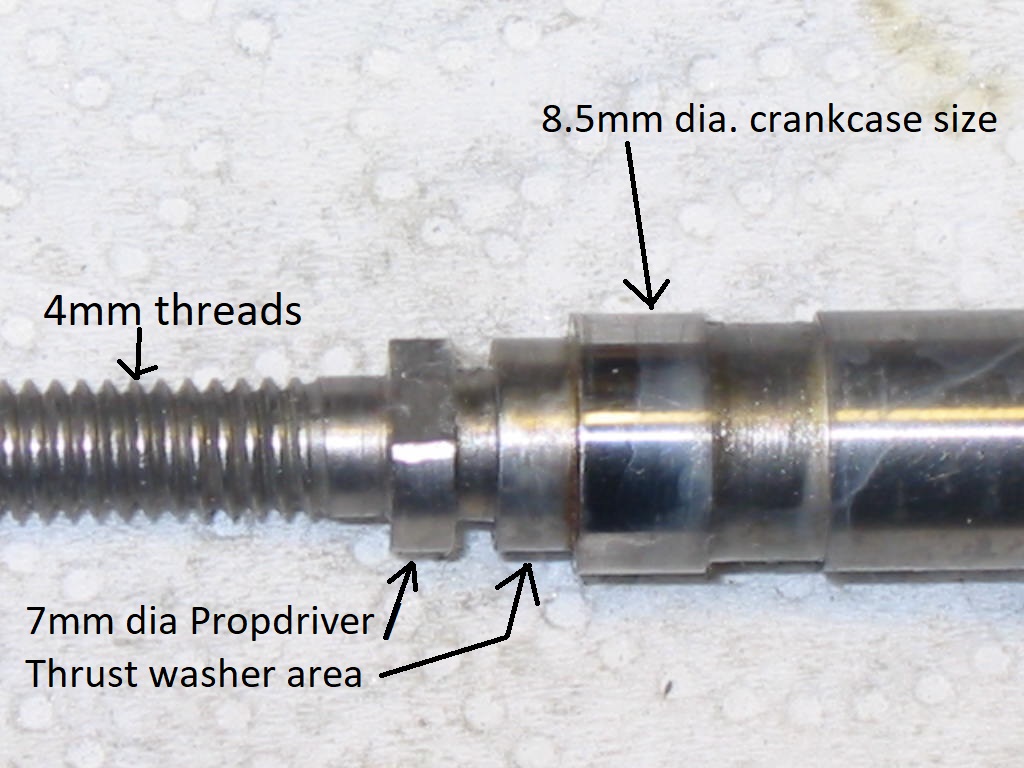

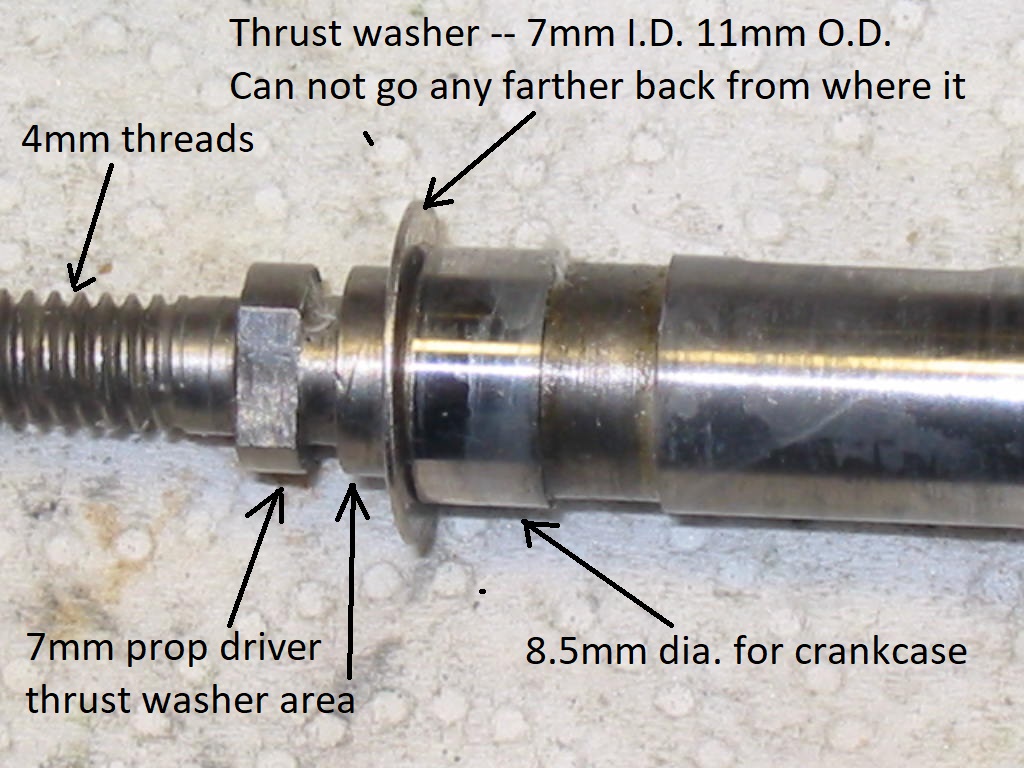

The bearing section on the crankshaft is 8.5mm and where the copper washer and prop driver is press on is 7mm.

So that copper washer I make is not a really a shim for the end play, just a guard for not having the crankcase and prop driver grind into each other and the crankshaft pin is shortened as to not gouge into the backplateand a little stock is removed off the backplate to clean up the gouging.

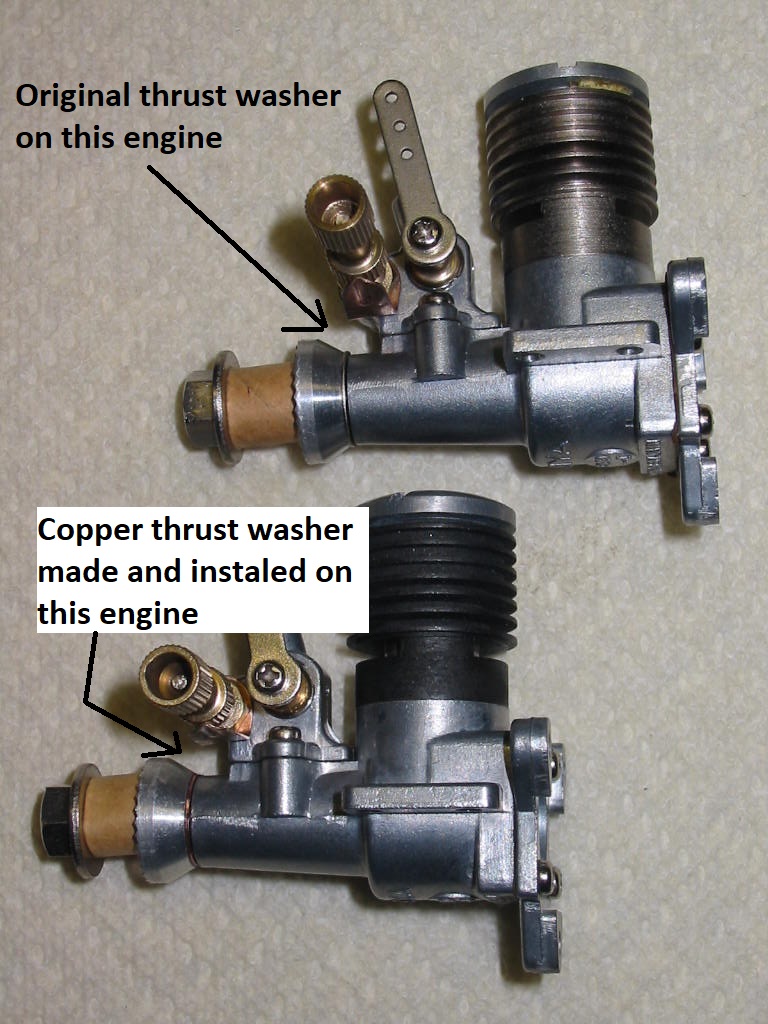

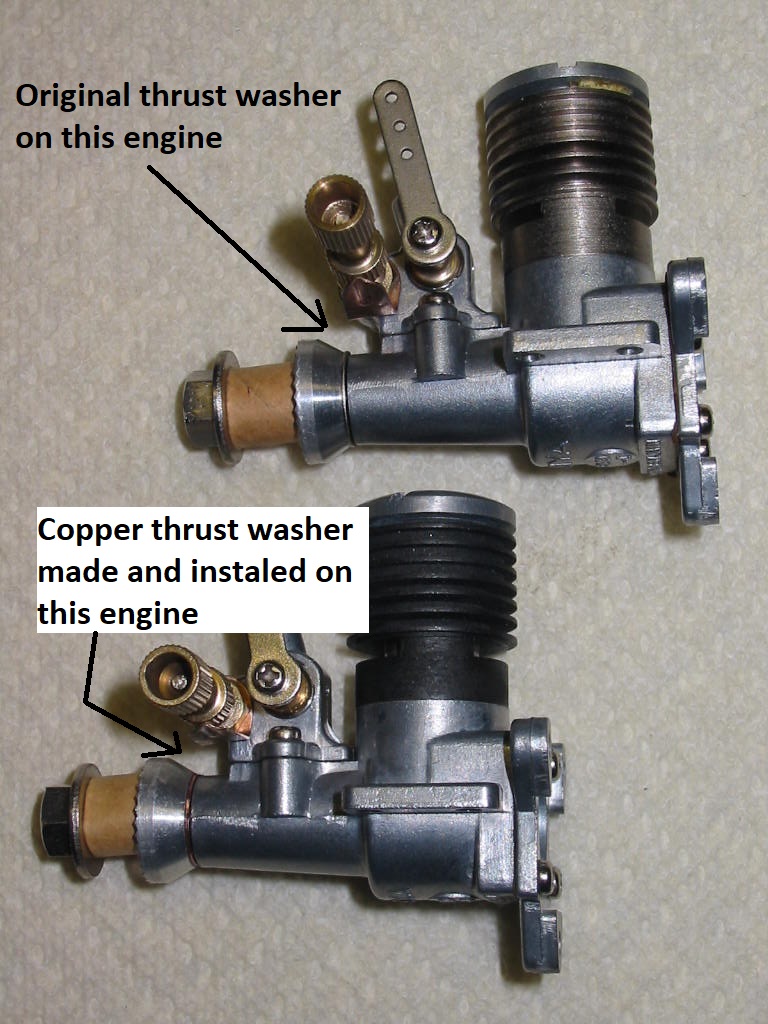

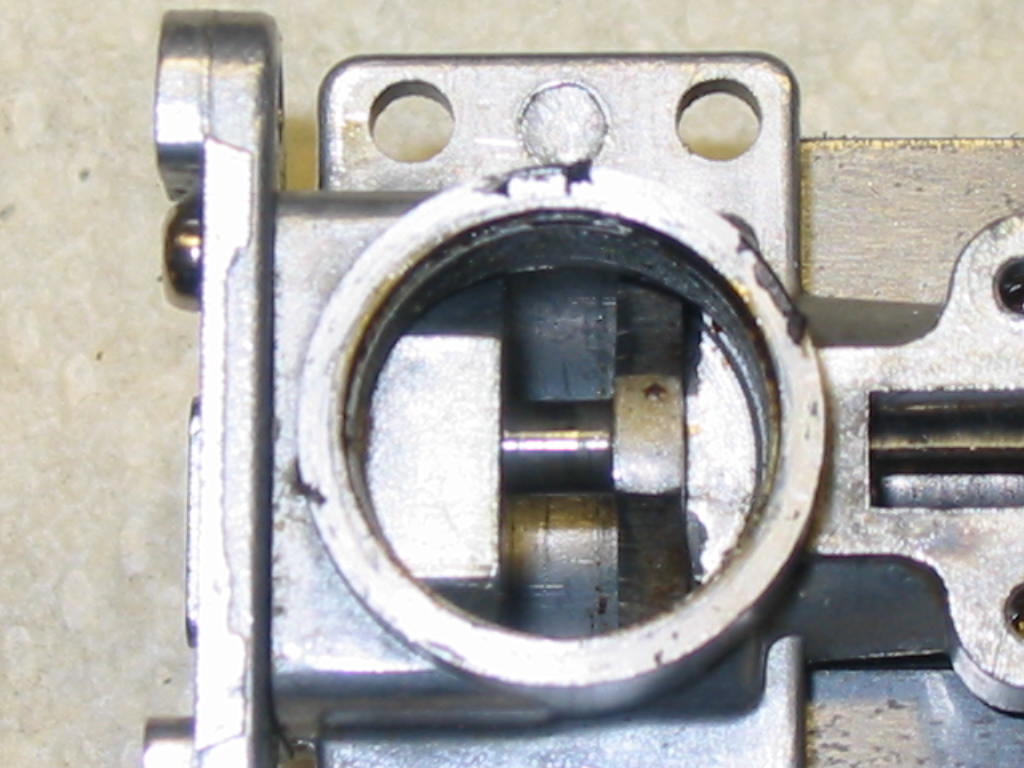

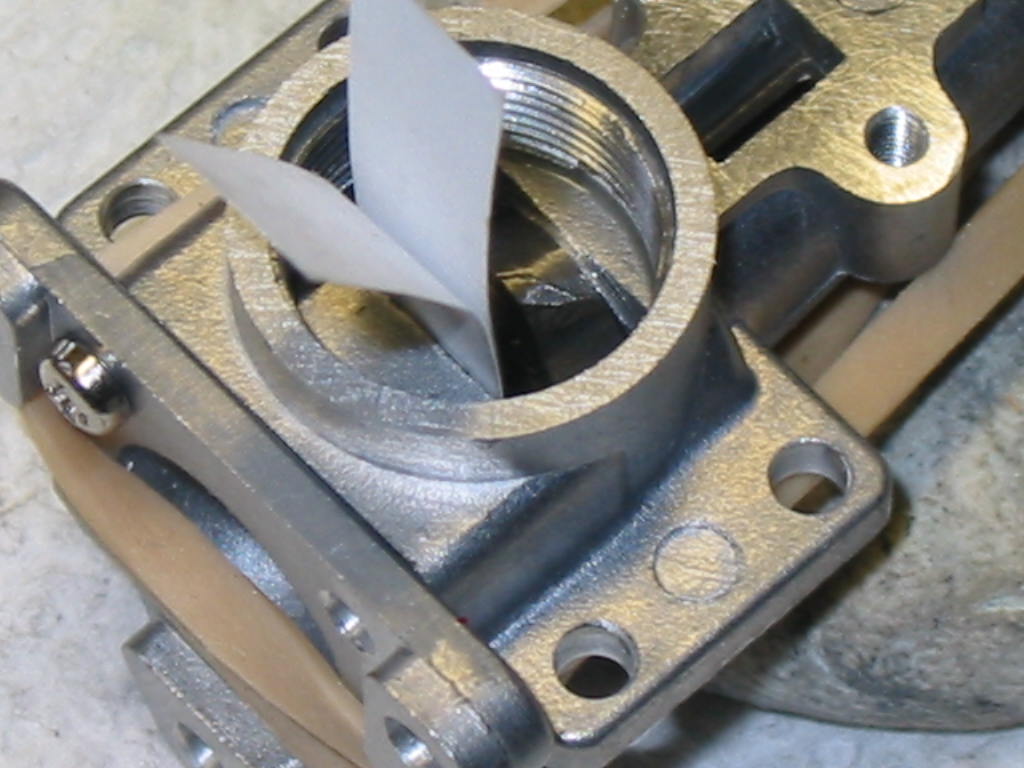

So, here are selected photos of the engine that I blue-printed and an original thrust washer on this engine with the crankshaft scoring the rear backplate.

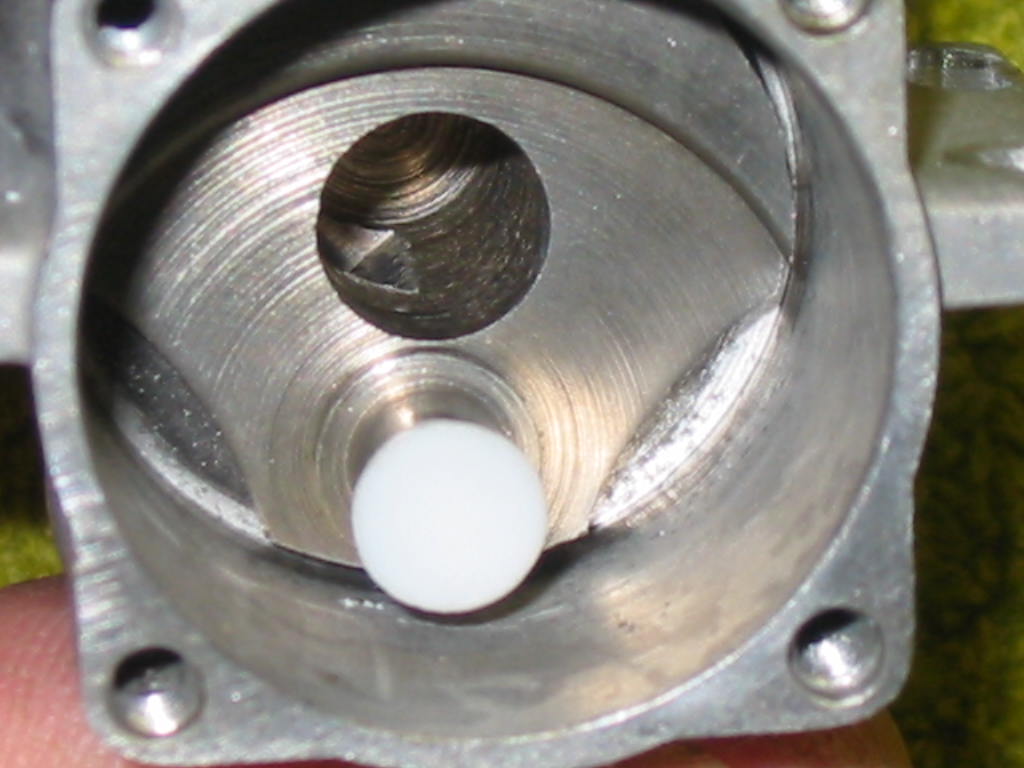

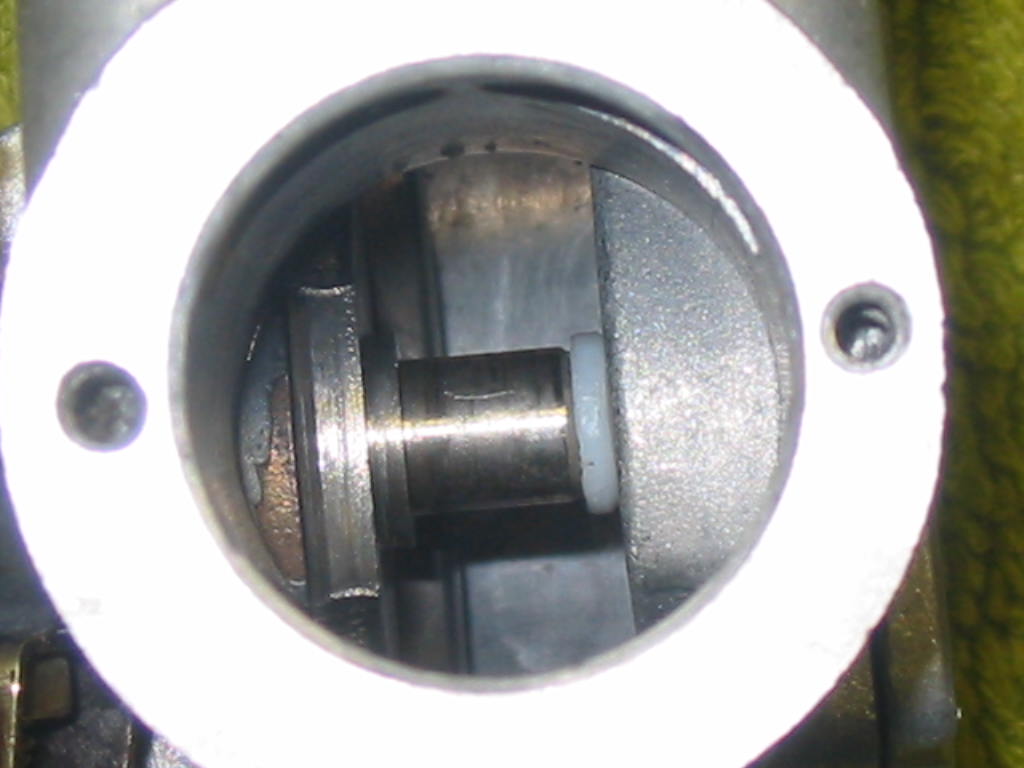

Photos of the crank pin in contact with the back plate:

Next is the photo of the prop washer driver and the original stainless steel thrust washer and the space between the thrust washer and the crankcase (as per Enya spec?) and the crankshaft pin is also touching the backplate.

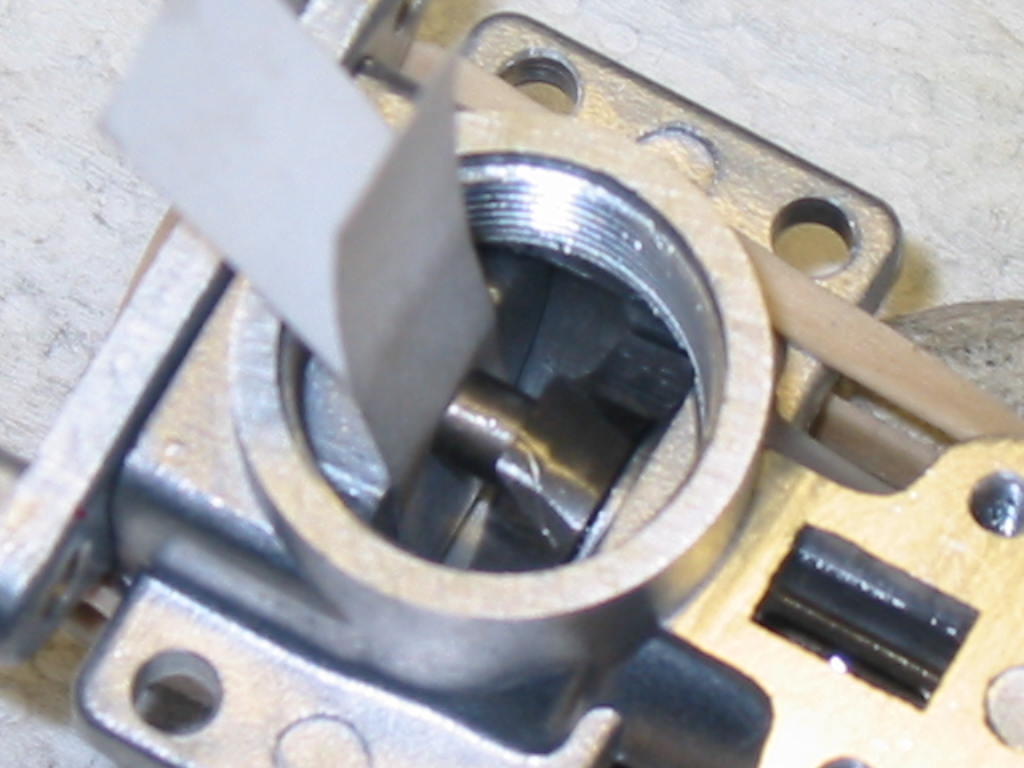

Now the photo of the scored backplate:

I removed some (a little) stock off the backplate and shortened the crankshaft pin by .200mm

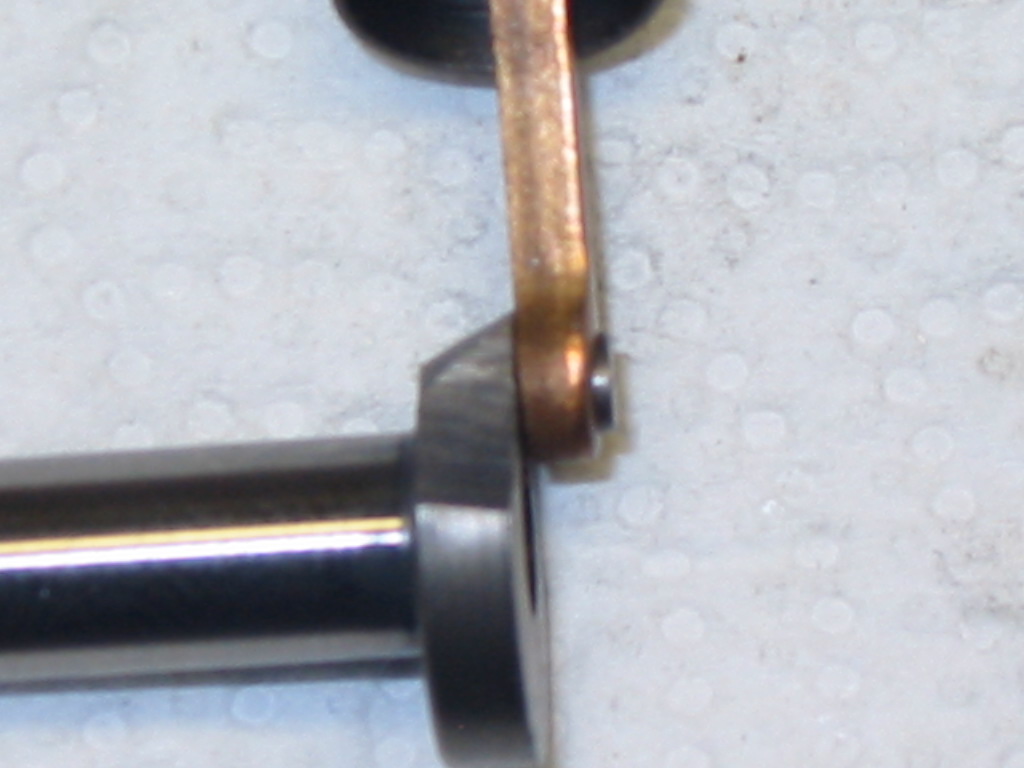

Photos of the crankshaft pin mod. (1st photo before/2nd photo after --- also put a chamfer on the pin end)

Next is about 0.100mm (or so) of stock removal from the backplate (to cleanup and remove the scoring on the backplate).

Last, now I checked the crankshaft fore/aft end play with the backplate installed (I did nothing to the original forward end play that was originally there as it was done by Enya).

Using a piece of paper (folded over = 0.150mm thick) I was able to just insert it between the back plate and the crankshaft pin.

This was done without the backplate's gasket which is the thin Enya gasket material at 0.250mm thick.

No matter how thick the thrust washer is (though a real thick one will give the prop driver washer a problem) the fore/aft play on the shaft is the same as it originally was from Enya when the engine was built.

The washer stops when it hits the bigger diameter (8.5mm) as the id of the washer is 7mm.

The missing washer is just so that the harder engine case doesn't wear down the back of the prop drive washer.

I have photos somewhere on my computer of an Enya engine missing the thrust washer and I had to purchase from Ken a new backplate and a new prop driver washer --- it was that bad without the thrust washer.

Maybe he ran it backwards or liked using a starter on the Enya .06-II engine?

[b]Below is the photo of the thrust washer (not a shim-spacer) on the crankshaft.[/b]

I'm not adding or reducing the crankshaft play by adding the copper thrust washer.

I'm adding the copper washer to reduce/eliminate the excessive wear between the prop drive washer and the crankcase.

And making sure the proper clearance is available between the crankshaft pin and the back plate.

Without the copper washer (thrust washer) there is excessive wear on the prop driver washer which then increases the crankshaft end play to where it starts to gouge into the backplate.

I was told years ago from an old engine rebuilder (not Clarence Lee) he was a SAM member for yeas who passed away a couple years ago who lived in Texas (did a great job on my Aurora Mills - plating the piston and other stuff to make it a good running engine). Anyway, he told me to use copper washers between the aluminum prop driver and the aluminum crankcase as it has a less of an expansion rate over the aluminum and it is a better aterial for the application.

sosam117- Diamond Member

- Posts : 1292

Join date : 2016-03-23

Location : Suburb of Chicago, Illinois

Re: Blue printing an Enya engine (this happens to be an .049-II Series #4)

Re: Blue printing an Enya engine (this happens to be an .049-II Series #4)

GallopingGhostler wrote:My 1965 OS Max .10R/C I acquired in 1974 from now long gone Hobby Shack has a stainless steel thrust washer. Mr. Ogawa recognized a need for it, and so spared no expenses in providing it. Those OS's are jewels of an engine. With only a ganged rotating exhaust baffle plate to the carb link, at 3.1 oz. weight, they make a nice upgrade to half-A's with considerably more power swinging a 7x4 prop than a .049 reedie. Noise wise, at full throttle same noise volume as a reedie; at half throttle like muffled; at idle, ultra quiet. (This is why I have 3.)

Out of curiosity, I did a look-see on Brinell Hardness for various metals, https://drill-hq.com/2011/11/hardness-scale-for-various-materials/ . Pure copper is softer than aluminum, K&S sheet is 110 Copper also used in electrical service.

Regardless, Cox used Phenolic washers on their Tee Dee engines which is softer, so probably a non-issue.

Advantages of "rolling your own" as @sosam117 did, is you can have on hand extra replacements. Since most needed in idle if a tractor engine, then it is there only to prevent crankshaft slap. Time would tell but like in all things, the ease in punching them out makes for a useful "gap filler".

It may also be useful on the legacy cross scavenge engines such as the Testor McCoy's and K&B Torpedoes and Stallions. They usually have a liberal amount of play.

Both use a nylon Crank Throw Spacer to prevent the hollow crankshaft connecting rod pin and connecting rod end from contacting the backplate. I do hand flipping chicken stick style versus any form of electric start, because it is easy to damage the nylon Spacer.

With a lack of this special nylon Spacer, I have found that an aluminum 1/8th inch dia. pop rivet fits perfectly without the shank. However, it being a tougher aluminum could possibly cause galling to the backplate especially if an electric starter is used, but I hand start.

Otherwise, during run, it floats, so I dressed the domed rivet head with a file to remove burrs then polished it. Long term, I don't think it will be a problem. But, I only do this because they are my engines and I am free to do with them as I like.

When I rebuilt my old McCoy engines, I made my own buttons for the end of the crankshaft.

MECOA didn't have any "in stock."

Below are photos of my progression of making the buttons out of Teflon which should last forever as I don't run them any more.

sosam117- Diamond Member

- Posts : 1292

Join date : 2016-03-23

Location : Suburb of Chicago, Illinois

Re: Blue printing an Enya engine (this happens to be an .049-II Series #4)

Re: Blue printing an Enya engine (this happens to be an .049-II Series #4)

Mike, work looks excellent, your way is far better than mine. Mine was more of those quick fixes from checking my hardware bins.

Aluminum pop rivet as a crank throw spacer.

And I hear you regarding when time to cash in the chips. I retired early because things at work changed, and it was worth leaving 2 years earlier at a slight reduction in retirement salary than the hassles of staying on. No regrets.

Aluminum pop rivet as a crank throw spacer.

And I hear you regarding when time to cash in the chips. I retired early because things at work changed, and it was worth leaving 2 years earlier at a slight reduction in retirement salary than the hassles of staying on. No regrets.

GallopingGhostler- Top Poster

Posts : 5330

Join date : 2013-07-13

Age : 70

Location : Clovis NM or NFL KC Chiefs

Re: Blue printing an Enya engine (this happens to be an .049-II Series #4)

Re: Blue printing an Enya engine (this happens to be an .049-II Series #4)

Gents I draw your attention to one of my favorite (yes even though I live in NZ) go-to places: www.modelfixings.co.uk a veritable Aladdin's cave of 'useful tings' ........in particular-in light of this thread, I draw your attention to: https://www.modelfixings.co.uk/shim_washers.htm

Note these are available in three thicknesses;).1mm, 0.3mm and 1mm.....or in your money: 4 thou, 12 thou, or 40 thou....those steps allow you to tailor adjust clearance down to a fine degree...and being stainless steel, they tend to be of similar-or the same-material as the OEM uses for shim washers-which certainly in recent times-say the past 30 years or so-were generally stainless, though some earlier makes and models used straight shim steel, often blued to limit corrosion.

Whilst you're perusing, take time to check out the rest of the website......

ChrisM

'ffkiwi'

Note these are available in three thicknesses;).1mm, 0.3mm and 1mm.....or in your money: 4 thou, 12 thou, or 40 thou....those steps allow you to tailor adjust clearance down to a fine degree...and being stainless steel, they tend to be of similar-or the same-material as the OEM uses for shim washers-which certainly in recent times-say the past 30 years or so-were generally stainless, though some earlier makes and models used straight shim steel, often blued to limit corrosion.

Whilst you're perusing, take time to check out the rest of the website......

ChrisM

'ffkiwi'

ffkiwi- Gold Member

- Posts : 362

Join date : 2018-07-10

Location : Wellington, NZ

Re: Blue printing an Enya engine (this happens to be an .049-II Series #4)

Re: Blue printing an Enya engine (this happens to be an .049-II Series #4)

ChrisM,

Here in the "States" (USA) I can go to McMaster-Carr and get the Metric Shim Washers DIN 988 in metric and inch.

For me I have a punch set in Metric and Inch (Metric for 2mm to 26mm in 2mm increments and the Inch set starting at 1/8" to 1" and incremental by 1/8")

As for the copper, it was left over cut-offs from the copper flashing from re-roofing the house and I also can at the local hobby shop purchase 12-inch (30cm x 30cm) squares of K&S copper sheets of different thickness.

So, I'm putting to use some good copper for a purpose, as I already have paid for the copper?

Also gives me a good reason to use my punch sets.

I could order the shim washers online from McMaster-Carr and have them shipped to my house.

Or drive 10~15 miles and pick the order up?

Here is the web page for McMaster-Carr:

https://www.mcmaster.com/products/din-988-shims/

Thanks ChrisM ---- I could have gone that way for the shims.

I did look at that first but didn't know how many I would need?

The quantity is what turned me off as I didn't know if I would use 25~50 shims?

Here in the "States" (USA) I can go to McMaster-Carr and get the Metric Shim Washers DIN 988 in metric and inch.

For me I have a punch set in Metric and Inch (Metric for 2mm to 26mm in 2mm increments and the Inch set starting at 1/8" to 1" and incremental by 1/8")

As for the copper, it was left over cut-offs from the copper flashing from re-roofing the house and I also can at the local hobby shop purchase 12-inch (30cm x 30cm) squares of K&S copper sheets of different thickness.

So, I'm putting to use some good copper for a purpose, as I already have paid for the copper?

Also gives me a good reason to use my punch sets.

I could order the shim washers online from McMaster-Carr and have them shipped to my house.

Or drive 10~15 miles and pick the order up?

Here is the web page for McMaster-Carr:

https://www.mcmaster.com/products/din-988-shims/

Thanks ChrisM ---- I could have gone that way for the shims.

I did look at that first but didn't know how many I would need?

The quantity is what turned me off as I didn't know if I would use 25~50 shims?

sosam117- Diamond Member

- Posts : 1292

Join date : 2016-03-23

Location : Suburb of Chicago, Illinois

Similar topics

Similar topics» Enya .049 glow engine

» Special tuned Enya .049-II Series-4 engine

» Vintage Tiger muffler/silencer for the Enya .09 or Enya .09-II engine.

» Standard Enya .049-II engine vs. the Mikoken Enya engine -- What is different?

» New in Box Enya .10 Series #4 engines

» Special tuned Enya .049-II Series-4 engine

» Vintage Tiger muffler/silencer for the Enya .09 or Enya .09-II engine.

» Standard Enya .049-II engine vs. the Mikoken Enya engine -- What is different?

» New in Box Enya .10 Series #4 engines

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules